Automated Quality Inspection for Automotive — AI in Action

Automated Quality Inspection for Automotive — AI in ActionIn the world of automobile manufacturing, quality is the cornerstone of a brand’s reputation and success. Ensuring the production of flawless vehicles is a meticulous task, and it often involves multiple forms of inspection along the assembly line. Visual inspections, aerodynamic optimization, and increasingly, sound analytics, all play critical roles in achieving excellence.This blog post shines a spotlight on the captivating realm of sound analytics, a vital component of quality inspection, and the technological advancements byteLAKE, Intel® and Lenovo are going to showcase at the upcoming SC23 conference in Denver, Colorado.Check out my other two posts in this three-part mini-series, where I provide summaries of byteLAKE’s plans for SC23 and the technologies we will be demonstrating there:AI is everywhere, but what more can it bring to Manufacturing and Automotive in specifics? Explore these AI solutions during the SC23 conference in Denver, Colorado. | by Marcin Rojek | Oct, 2023 | MediumAccelerating Time to Insights for Automotive — Live Demo and Presentation at SC23 in Denver, Colorado. | by Marcin Rojek | Nov, 2023 | Medium.AI-assisted Sound Analytics (automotive)Sound Analytics: A Symphony of Quality AssuranceImagine this: Microphones connected to highly-trained AI models, diligently record the symphony of sounds produced by car engines as they come to life. These AI systems are not just listening; they’re meticulously dissecting each note to detect irregularities, inconsistencies, or potential issues. In an era where excellence is non-negotiable, AI-driven sound analytics is taking the wheel.But why the emphasis on sound analytics? Because it goes beyond mere quality control. By pinpointing issues during the assembly process, this technology doesn’t just bolster production efficiency; it also enhances the end-user experience. Fewer recalls, increased reliability, and a sterling reputation are just a few of the dividends paid by the integration of AI into the quality control process.Humans and AI: The Power of SynergyIt’s essential to clarify that AI isn’t here to replace the human touch but to complement and empower it. In fact, AI serves as a force multiplier for human operators, exponentially increasing accuracy. For example, when humans monitor quality, they might achieve, say, 80% accuracy. When humans and AI join forces, that number skyrockets to 99%. Not to mention, AI never tires or gets bored, making it an invaluable asset for maintaining stringent quality control standards 24/7 in demanding, noisy environments.Humans and AI — delivering better quality togetherThe magic happens when humans leverage these tools to unleash their own creative potential. As AI takes on routine and repetitive tasks, humans are liberated to innovate and pioneer new approaches. The introduction of AI into the manufacturing landscape is akin to giving inventors a new set of tools and, ultimately, broadening the horizons of possibility.The Edge of ManufacturingIn manufacturing, data processing must often occur close to the source and in real time. Enter Edge Computing, a technology that’s at the heart of contemporary manufacturing. It’s the engine that drives AI analytics, ensuring that issues are identified as they arise. While cloud solutions have their place for backup and extensive data storage, Edge AI is the real-time answer.Edge AI — what it means for industriesOptimizing the Future: Edge AI and BeyondThe Inference market, a pivotal component of AI, is set to grow exponentially, forecasted to be four times the size of the AI training market, with a long tail that extends far and wide.Scalability is the name of the game, and we’re determined to put the future of manufacturing in the hands of innovation pioneers.https://medium.com/media/d2099a2634560d71624e2a7fe6f1c622/hrefAutomated Quality Inspection for Automotive — AI in Action was originally published in Becoming Human: Artificial Intelligence Magazine on Medium, where people are continuing the conversation by highlighting and responding to this story.

Automated Quality Inspection for Automotive — AI in Action

In the world of automobile manufacturing, quality is the cornerstone of a brand’s reputation and success. Ensuring the production of flawless vehicles is a meticulous task, and it often involves multiple forms of inspection along the assembly line. Visual inspections, aerodynamic optimization, and increasingly, sound analytics, all play critical roles in achieving excellence.

This blog post shines a spotlight on the captivating realm of sound analytics, a vital component of quality inspection, and the technological advancements byteLAKE, Intel® and Lenovo are going to showcase at the upcoming SC23 conference in Denver, Colorado.

Check out my other two posts in this three-part mini-series, where I provide summaries of byteLAKE’s plans for SC23 and the technologies we will be demonstrating there:

- AI is everywhere, but what more can it bring to Manufacturing and Automotive in specifics? Explore these AI solutions during the SC23 conference in Denver, Colorado. | by Marcin Rojek | Oct, 2023 | Medium

- Accelerating Time to Insights for Automotive — Live Demo and Presentation at SC23 in Denver, Colorado. | by Marcin Rojek | Nov, 2023 | Medium.

Sound Analytics: A Symphony of Quality Assurance

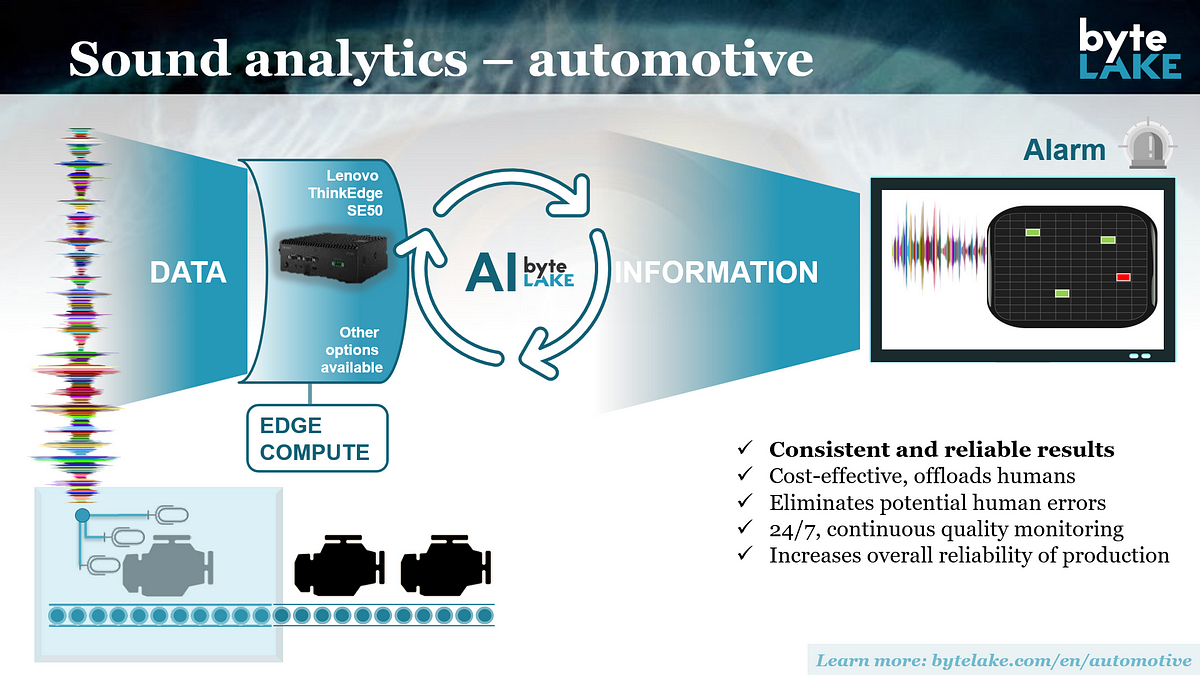

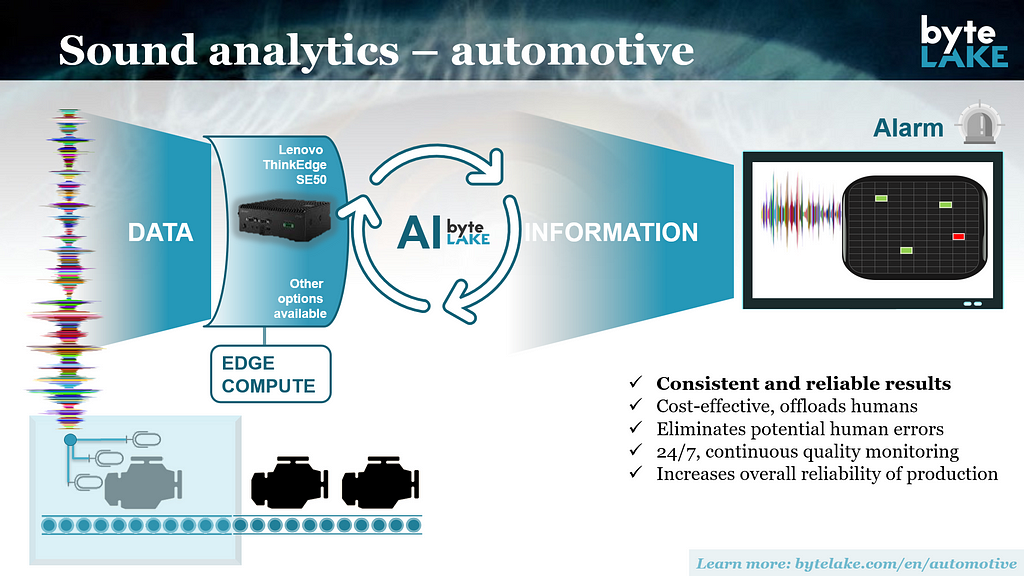

Imagine this: Microphones connected to highly-trained AI models, diligently record the symphony of sounds produced by car engines as they come to life. These AI systems are not just listening; they’re meticulously dissecting each note to detect irregularities, inconsistencies, or potential issues. In an era where excellence is non-negotiable, AI-driven sound analytics is taking the wheel.

But why the emphasis on sound analytics? Because it goes beyond mere quality control. By pinpointing issues during the assembly process, this technology doesn’t just bolster production efficiency; it also enhances the end-user experience. Fewer recalls, increased reliability, and a sterling reputation are just a few of the dividends paid by the integration of AI into the quality control process.

Humans and AI: The Power of Synergy

It’s essential to clarify that AI isn’t here to replace the human touch but to complement and empower it. In fact, AI serves as a force multiplier for human operators, exponentially increasing accuracy. For example, when humans monitor quality, they might achieve, say, 80% accuracy. When humans and AI join forces, that number skyrockets to 99%. Not to mention, AI never tires or gets bored, making it an invaluable asset for maintaining stringent quality control standards 24/7 in demanding, noisy environments.

The magic happens when humans leverage these tools to unleash their own creative potential. As AI takes on routine and repetitive tasks, humans are liberated to innovate and pioneer new approaches. The introduction of AI into the manufacturing landscape is akin to giving inventors a new set of tools and, ultimately, broadening the horizons of possibility.

The Edge of Manufacturing

In manufacturing, data processing must often occur close to the source and in real time. Enter Edge Computing, a technology that’s at the heart of contemporary manufacturing. It’s the engine that drives AI analytics, ensuring that issues are identified as they arise. While cloud solutions have their place for backup and extensive data storage, Edge AI is the real-time answer.

Optimizing the Future: Edge AI and Beyond

The Inference market, a pivotal component of AI, is set to grow exponentially, forecasted to be four times the size of the AI training market, with a long tail that extends far and wide.

Scalability is the name of the game, and we’re determined to put the future of manufacturing in the hands of innovation pioneers.https://medium.com/media/d2099a2634560d71624e2a7fe6f1c622/href

Automated Quality Inspection for Automotive — AI in Action was originally published in Becoming Human: Artificial Intelligence Magazine on Medium, where people are continuing the conversation by highlighting and responding to this story.

.jpg)

_0.png?itok=L6nb1tHp#)